DEF Filters - Keeping your catalyst and the environment clean

Diesel Exhaust Fluid or DEF filters are often overlooked during routine machine maintenance. These filters are part of the Selective Catalytic Reduction (SCR) system of diesel-powered vehicles such as tractors and forklifts. In recent years, worldwide legislation has driven a steep rise in the popularity of SCR technology, leading to a growing demand for more understanding about the topic. So let’s look at how this system works and why you must change the DEF filter regularly.

Why do diesel engines use Diesel Exhaust Fluid?

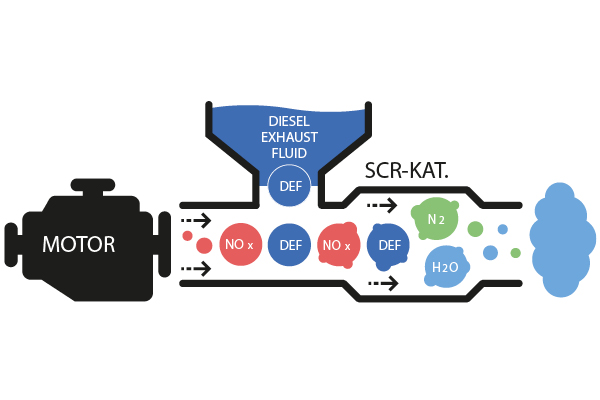

Selective Catalytic Reduction (SCR) technology has made a significant difference in improving the air that we breathe today. This technology uses Diesel Exhaust Fluid (DEF), also known as AdBlue®, to reduce harmful emissions and to comply with current emission standards.

A small pump injects DEF fluid into the untreated exhaust of your diesel engine. Mixing these two components ignites a chemical reaction that converts highly polluting Nitrogen oxides (Nox) into harmless Nitrogen (N2) and water (H2O). SCR catalysts are currently the preferred method for meeting diesel emission standards and reduce as much as 95% of Nitrogen oxide emissions.

What is DEF and why does it need filtering?

Diesel Exhaust Fluid is a liquid mixture of 32,5% urea and 67,5% deionised water. Unfortunately, the urea —an organic compound— has a tendency to crystallise. These crystals often lead to issues with the injection pump and the SCR catalyst, which ultimately leads to a machine standstill.

DEF filters offer the right protection against these crystal formations and other contaminants. They ensure optimal functionality of the DEF injection pump and keep the diesel SCR system working at peak performance.

How often should a DEF filter be replaced?

It’s important to note that DEF or AdBlue® filters don’t outlast the lifespan of your vehicle. Exhaust fluid contamination and injection pump defects can lead to SCR malfunction, putting your machine at a standstill.

For non-road vehicles, recommendations may vary per manufacturer. Changing the filter every 3 years or 3,000 hours, whichever comes first, is a good starting point.

Looking for DEF filters for your machine?

Go to our online shop to get yours today! TVH offers a wide range of DEF filters for various equipment makes and models.

The best way to find the right DEF filter is by using the machine details (make, model, etc.):

- Go to the search function in our online shop.

- Enter the machine details.

- Find the parts you need!

Or discover below a small selection we made for you.

Not 100% sure which part you need? Get in touch! Our technical advisors are happy to provide extra support.

Did you know we recently published a white paper discussing filters for small and medium-sized industrial vehicles? Check it out here.

Are you passionate about diesel technology? Turbocharge your knowledge with our hands-on training sessions about New diesel technologies and Diesel exhaust gas after-treatment & engine diagnostics.

You may also be interested in the following blogs:

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.

Request your account

Over 75.000 customers trust TVH as their spare parts supplier to ensure their client’s equipment fleet is running smoothly and efficiently. It starts with a customer account.