Optimal climate control through regular A/C maintenance

When operating a machine for several hours, comfort becomes increasingly important. One of those comfort aspects is climate control, through air conditioning or A/C. Winter or summer, rain or sunshine, you can keep the inner climate at a temperature of your choice. But to keep it working correctly, timely maintenance is key.

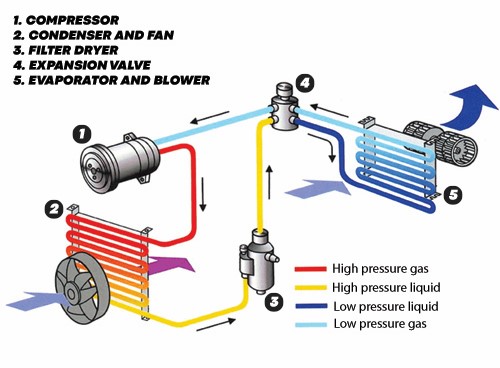

How does an A/C system work?

The A/C system is a closed circuit, containing a compressor, condenser, drier and an expansion valve. These are all connected through a piping system, filled with a coolant - typically R134a.

Air conditioning works by continually changing the coolant from a gas into a liquid and back. This is done by manipulating the pressure and temperature of the coolant. A compressor pushes the gaseous coolant through the system at a high pressure of around 10 - 15 bar. Subsequently, the condenser turns it into a liquid by lowering the temperature to 35 °C. Next to the condenser, the drier stops any remaining gas from entering the rest of the system. This way, the liquid can function at maximum efficiency.

The liquid flows to the expansion valve, where the pressure drops significantly to 1,2 - 2 bar and the temperature rises to 65 °C. This essentially comes down to ‘boiling’ the coolant and turning it into a gas. To accomplish this, a fan provides heat, extracting heat from its direct environment, including the cabin. The air gets cooled off and is blown back into the cabin, providing the cool air you want during hotter days.

The manipulation of the coolant is no mean feat and has its effects on the A/C system. Over time, particles break free from the different parts, polluting the coolant. This pollution can be collected by the drier, but this causes the drier to clog up, which warrants a replacement.

The need for maintenance

It goes without saying that the A/C system needs regular maintenance. This includes the replacement of different parts at determined intervals.

Light maintenance

During the boiling of the coolant near the evaporator, heat is extracted from the air, as well as moisture. This moisture clings to the condenser, decreasing its performance. Luckily, the condenser can easily be cleaned by wiping away the moisture. This needs to be done every 50 working hours. If the moisture isn’t taken care of, it creates the perfect environment for bacteria to thrive, creating foul odours. If that’s the case, you need to replace the evaporator and possibly the cabin air filter as well.

Special care

Next up is the coolant, which requires special attention. The coolant has multiple functions:

Its primary function is heat extraction, providing cool air to the cabin.

It also contains a specific amount of oil, which is employed to lubricate the compressor.

A small amount of UV liquid is added to the mix. In case of leaks, these can quickly be detected by using a UV light.

The coolant needs to be in mint condition for the whole A/C system to function at full capacity. So, it needs to be checked yearly. Does the coolant contain any pollution? If so, it needs to be removed. Does the system still contain the right amount of coolant? After all, an A/C system can lose as much as 10% of its coolant every year. This has a direct impact on its performance, as well as fuel consumption: the engine needs to help the A/C system in order to achieve the same performance.

It can also have graver effects: if the amount of coolant is too low, there’s also not enough oil for the compressor, which can get heavily damaged.

Fortunately, a checkup of the coolant is relatively easy with an A/C service station. Connect the machine to the A/C system and the service station will determine the amount of coolant within the system. Simultaneously, the machine can check the system for any leaks. This way, the service station can perform two tasks in one go.

Be thorough

Every two years, the A/C system needs to undergo a thorough checkup to ensure optimal performance. For instance, the drier needs to be replaced as the collected particles decrease its performance.

Additionally, the inside of the A/C system needs to be cleaned thoroughly, using the A/C station. This service station puts the whole system into a vacuum, essentially sucking out any remaining coolant or particles. Any possible presence of moisture within the system is removed as well.

Afterwards, a determined amount of new coolant (with a specific amount of oil and UV fluid) is added to the A/C system.

Pro tip: Use the A/C throughout the whole year! This way, every part is kept lubricated by the system flow. If the system has fallen into disuse, the compressor loses lubrication and gets too hot. This will cause failure and high replacement costs.

Keep it cool and comfortable with TVH

The maintenance of an A/C system is a vital part of keeping it comfortable for the operator. Thanks to our comprehensive range, TVH has everything you need to maintain the A/C system, keeping it up and running and keeping it comfortable within the cabin.

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.

Request your account

Over 75.000 customers trust TVH as their spare parts supplier to ensure their client’s equipment fleet is running smoothly and efficiently. It starts with a customer account.