Precision in motion: the importance of MEWP joysticks

Naturally, working at height and safety are inextricably linked. Sturdy mobile elevating work platforms (MEWPs) may look infallible, but safety is vital when using them. It is one of the reasons why the Learning hub has previously covered accessories to maximise MEWP safety and the importance of foam-filled tyres for machine stability. Another way to improve safety is by ensuring the MEWP is in perfect working order, which includes joysticks and control boxes. After all, these parts are responsible for all movements of the machine.

Joysticks, masters of control

Mobile elevating work platforms such as scissor lifts and boom lifts allow users to perform tasks at heights or hard-to-reach areas in complete safety. But to get there, the operator must be able to control the MEWP as accurately as possible. This is where joysticks come in. Joysticks, and by extension the control box, take care of all machine movements, from steering to operative movements. The control box also houses several built-in safety features, such as an emergency stop button, a horn button, a drive speed selection button, and others.

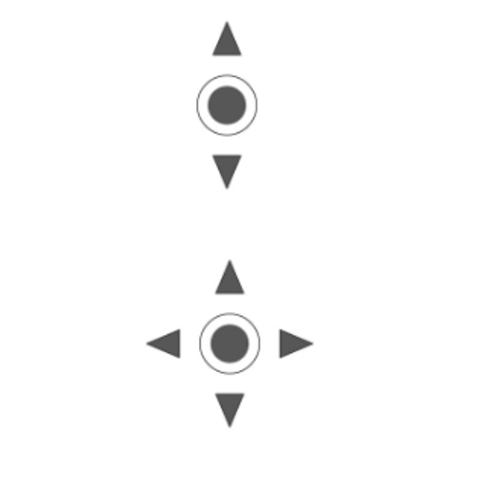

Depending on the type and make, the machine has one or more joysticks responsible for a specific movement: steering, horizontal or vertical movements, or rotation. Typically, these joysticks are either single-axis or dual-axis:

- Single-axis or two-way joysticks are limited to simple movements because they can only move in two directions: forward and backward or left and right. These are also used for the ascending and descending movements of MEWPs.

- Dual-axis or four-way joysticks can move in four directions: forward/backwards and left/right, either in a cross-shape or circular motion.

The lifespan of joysticks

Joysticks are essential to the safe operation of mobile elevating work platforms, so they must be in perfect working order. However, like all machine components, they are also subject to wear and tear. They are used intensively and will show signs of mechanical wear and defects over time. Depending on the type, joysticks have an average lifespan of about 2 to 10 million movements. But this lifespan can also be reduced as a result of, for example, the improper use of the joysticks or the extreme weather conditions to which outdoor MEWPs are regularly exposed. It is, therefore, important that the machine operator inspects the joysticks before each use.

Replacing joysticks

When inspection shows that replacements are needed, TVH can supply the necessary parts thanks to our wide range of joysticks:

- Joysticks and electronic levers with analogue switches (NO + NC and combinations) in two- and four-way versions

- Joysticks with digital Hall effect switches in two- and four-way versions

- Proportional joysticks with potentiometers in two- and four-way versions

- Proportional joysticks with Hall effect sensors in two- and four-way versions

These joysticks —and control boxes, by extension— are suitable for many makes and models of mobile elevating work platforms, including Airo, Dinolift, Genie, Haulotte, JLG, Manitou, MEC, Niftylift, Sinoboom, Skyjack, Snorkel, Teupen, Upright, Zoomlion, and more.

Ordering replacements

To ensure you order the right joysticks and control boxes, relatively limited information is required. In most cases, knowing the machine details —meaning make, model and serial number— suffices to find the correct replacements. When you turn to TVH to find the right part, it is helpful if you send us detailed pictures that also include the labels on the parts.

Installing replacements

Although most joysticks are plug-and-play, a few settings occasionally require some work during installation. If this is the case, we always include the corresponding instructions with the joystick’s packaging.

Remanufactured joysticks

If a new part isn’t what you are looking for, we can also help you with our extensive range of remanufactured joysticks. These are used parts that have been expertly repaired and restored by our highly qualified technicians and engineers. To remanufacture a joystick, they repair all input devices, replace any faulty parts and replace all the wearing parts. Then, the joystick is put through extensive functionality testing to ensure it is in an "as-new" condition and will be as reliable as the original product. In this way, by choosing remanufactured joysticks, you get the same high quality, a one-year warranty and savings of up to 50%.

Looking for joysticks and control boxes?

- Go to our online shop to check out and buy our full range of joysticks and control boxes for mobile elevating work platforms.

- Read more about our range in the ‘Parts that keep MEWPs going’ brochure.

- Having a hard time finding what you’re looking for? Don’t worry! You can always contact us if you have questions; we are happy to help.

About the authors

This blog post is brought to you by your construction equipment marketing team.

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.

Request your account

Over 75.000 customers trust TVH as their spare parts supplier to ensure their client’s equipment fleet is running smoothly and efficiently. It starts with a customer account.