TVH’s 100,000 remanufactured parts that make you unstoppable!

TVH remanufactures over 100,000 parts each year. That’s one of the many ways the company contributes to a cleaner planet and supports the circular economy. What once started as a small business segment is now one of TVH’s fastest-growing departments. And the best part? Everybody wins! Did you know that buying remanufactured parts can save our customers up to 50% compared to new ones?

Environmental sustainability

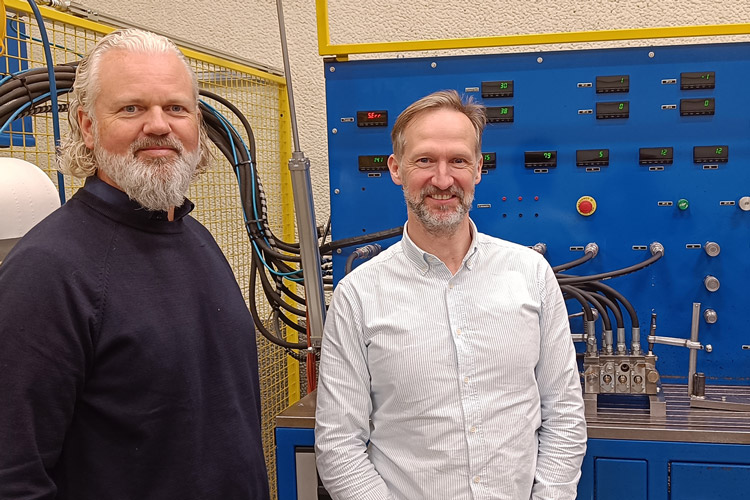

Lorenz Verfaillie (Director Electronics, International) and Joffrey Deylgat (Manager of Remanufactured Parts) have been at the grassroots of TVH’s remanufacturing operations for nearly 30 years.

“At TVH, we highly value sustainability and environmental responsibility,” explains Lorenz. “We firmly believe in the circular economy and are convinced that waste should be avoided at all costs. Following the cradle-to-cradle concept, we keep our remanufactured parts in circulation, prevent the need to produce more parts and reduce the consumption of even more raw materials. If we find that a part cannot be remanufactured, then we recycle it correctly so that its resources can be reused.”

Parts & partnerships

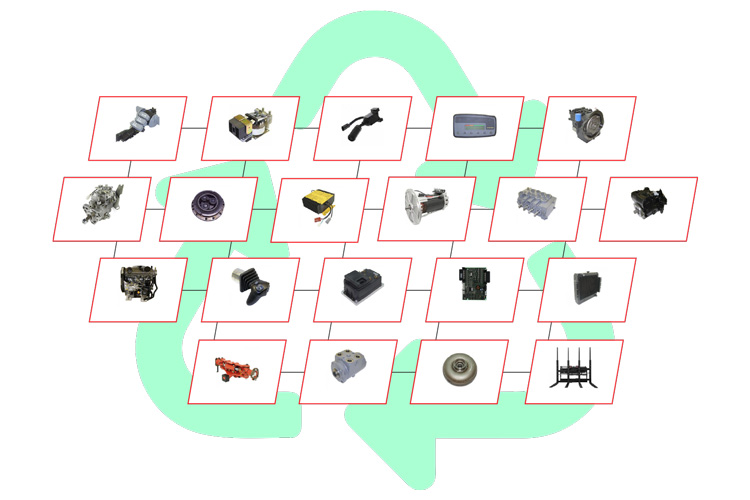

More than 250 expert technicians and engineers now work for TVH’s global remanufacturing operations. They work on various hydraulic, mechanical, electric and electronic parts.

“We’ve been remanufacturing PCBs, joysticks and motor controllers since 1995,’ says Lorenz, ‘but it’s important to stay up to date with the latest technologies. This allows us to increase our market share in the field of electronic remanufacturing and electrification. For example, we now also offer an Electric System Design service, which helps you electrify your existing equipment.”

TVH’s remanufacturing division is also a certified service centre for several prominent part manufacturers such as Bosch Rexroth, Curtis, Parker, Sevcon, Carraro and Danfoss. These partnerships underpin the company’s position as a reliable supplier of quality products with technical expertise.

Quality guaranteed by standard processes

Unlike a standard repair, remanufacturing involves fully disassembling the part, replacing worn and damaged components and restoring it to like-new condition. Before going to stock, the part is thoroughly tested and receives a fresh coat of paint.

“In the past few years, we have heavily invested in new state-of-the-art test benches,” explains Joffrey. “Only the highest quality standards are good enough, and we make sure that every part that leaves the workshop works like new. We guarantee this to our customers by giving them the same 1-year warranty they get when buying new parts.”

To ensure consistent quality, the engineers always follow the same procedures.

- Initial inspection: Before dismantling any parts, they are subjected to an initial inspection.

- Dismantle: After a positive evaluation, parts are carefully disassembled for further inspection.

- Clean and repair: All components are thoroughly cleaned and inspected. Broken and worn parts are replaced.

- Reassemble: The components are reassembled to their original state following standardised procedures.

- Quality check: The parts are checked on one of TVH’s state-of-the-art test benches.

- Coat: If applicable, parts get a coat of fresh paint or varnish and end up looking like new.

Future outlook

Remanufacturing is an evident success at TVH. "Our workshops operate at full capacity, and we're expanding our hydraulic and electromechanical workshop in Belgium into a larger building,” says Joffrey. “This will increase our surface area by 50% and allow us to meet the growing demand from customers who want to be a part of a more sustainable future.”

“The Electronics department is also expanding,” explains Lorenz. “Our US FSIP division is preparing the construction of a larger building, and we’re enlarging our workshop in Belgium too.”

Take part in the circular economy!

You can take an active role in the circular economy today by selling your old and used parts to TVH. We’ll remanufacture and test the part to the highest standards before putting it back on the market. Get in touch to learn more and earn money!

Remanufactured parts can save you up to 50% and offer a great alternative when you’re looking for spare parts. And to give you total peace of mind, remanufactured parts come with a 1-year warranty, just like our new parts. Visit TVH Remanufacturing and discover more. Ready to contribute to a cleaner planet? We sure are!