Pneumatic tyres vs. solid tyres: an informed choice

Comfort, safety and productivity are the three main factors that influence the choice between pneumatic and solid tyres. Your choice ultimately depends on the equipment you use and the type of work you do. Whether you drive a forklift or a skid steer loader and work inside a food processing plant or on the shipping docks, it all matters.

Let’s investigate which type of tyre works the best for you.

Pneumatic tyres

Pneumatic tyres offer the most comfortable driving experience as they absorb the shocks of rough terrain. When inflated at the correct pressure, they also provide optimal tyre traction. Consult your equipment’s tyre pressure chart for more information.

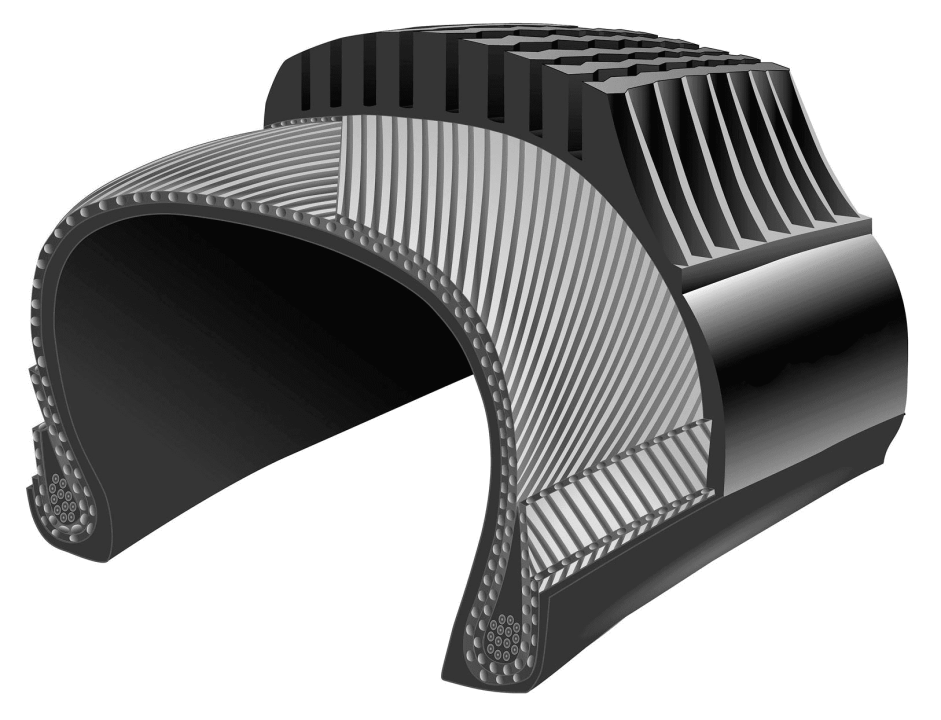

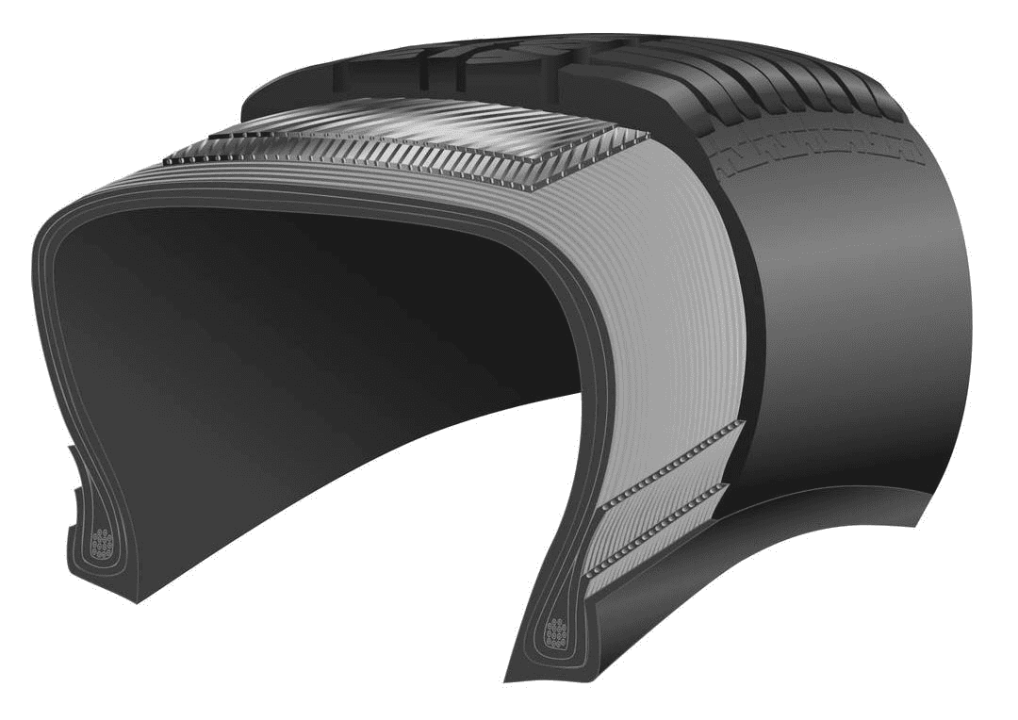

Cords inside the tyre rubber (usually made of nylon or steel) provide structural support and protect the tyres from cuts and punctures. The most popular pneumatic tyre designs are bias and radial tyres.

Bias tyres have multiple layers of cords inside them, fitted in a crisscross pattern. These cords span from side to side and reinforce the flanks, reducing the risk of cuts and punctures. Bias tyres are durable and a great choice when operating heavy loads at lower speeds.

Radial tyres have a single layer of protective cords. They run in parallel under the tread and protect the tyre from punctures. That makes them more flexible, lightweight and the best choice for vehicles operating at higher speeds.

Solid tyres

Solid tyres reduce the risk of punctures to zero. This is especially important when balancing loads, as is the case with forklifts, ground support equipment or sometimes MEWPs (Mobile Elevating Work Platforms). You could also be dealing with persistent punctures on difficult terrain. In these situations, airless tyres are the way to go. The only downside is that their speed is limited to 30 km/h.

Some solid tyres come with extra features.

Certain environments may require your vehicle to leave no traces on the floor. Use non-marking tyres in these situations. Food processing plants usually require this type of tyre as well. Non-marking tyres have a paler appearance than traditional tyres because of the absence of carbon black. This carbon extends the tyre’s lifespan but can leave marks on the floor and contaminate food products.

A solid tyre’s design causes more heat buildup than its pneumatic counterpart. They can also give you a “harder” driving experience. Choose solid tyres with holes (sometimes called aperture tyres) to combine the comfort of pneumatic tyres with the no-flat benefits of solid tyres. The apertures allow better heat dissipation, which extends the tyre’s life. Different hole designs also offer various levels of comfort.

Ordering new tyres

When it's time to replace the tyres of your forklift, skid steer loader or any other equipment, you can easily find the right type using your machine details (make and model):

- Go to our online shop.

- Enter your machine’s make and model.

- Browse the tyres you need!

Alternatively, you can search for the right tyres in the ‘Find Parts’ section on our online shop:

- Enter the tyre size.

- Choose the correct application.

- Browse the tyres you need!

Get in touch if you can't find the tyre you require. Our skilled colleagues are ready to give extra support.

Tempted by tyres? Learn all about them in the following blog posts:

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.

Request your account

Over 75.000 customers trust TVH as their spare parts supplier to ensure their client’s equipment fleet is running smoothly and efficiently. It starts with a customer account.