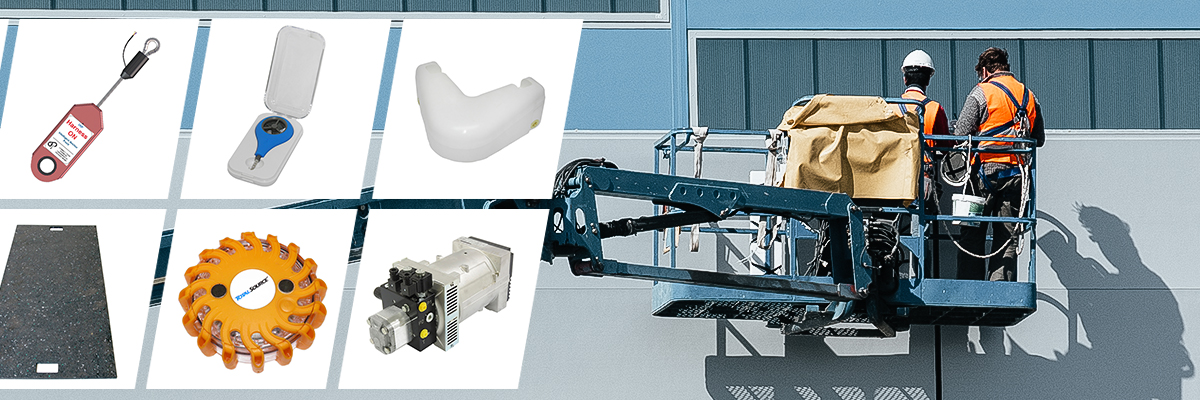

How to maximise MEWP safety and efficiency with accessories

To keep mobile elevating work platforms (MEWPs) going safely, it’s vital to get the right parts at the right time. But beyond excellent machine performance, there are many other ways to improve MEWP safety. Think of fall protection, warning lights to make the machine stand out in bad weather, outrigger pads to increase stability, etc. Next to these accessories, there are other types that can help protect the machine and the environment, and maximise efficiency. Discover some essential accessories here.

Fall protection

Requirements for fall protection when working with MEWPs such as scissor lifts and boom lifts vary from region to region. However, it is always advisable to use fall protection when operating these machines. If something goes wrong, fall protection arrests the fall, resulting in less severe consequences.

A fall protection kit is not restrictive as it provides sufficient slack and freedom of movement to perform tasks. Such a kit consists of the following components:

- A full-body harness,

- Anchor devices, to be attached to the correct anchor points on the MEWP,

- Coupling or connecting devices, for example, fall restraint lanyards.

Harness ON™

To further improve operator safety, add Harness ON™ to the fall protection kit. Harness ON™ is an intelligent anchor point that is permanently shackled to the MEWP’s anchor point and is electronically wired to the machine’s function controls. Until the operator clips a carabiner to the inductive ring of the Harness ON™, effectively connecting their harness to the machine, the MEWP won’t function. It’s an easy-to-use solution that doesn’t affect the operator’s work but has a big impact on safety. Moreover, Harness ON™ complies with EU and ANSI standards and is compatible with all machines.

Warning lights

Mobile elevating work platforms are ideal for working in hard-to-reach places. However, this means that the machine sometimes has to be parked in less-than-ideal conditions, such as bad weather or along a busy road. To make sure the MEWP stands out, it’s advisable to use warning lights. The lights are magnetic, so they can be quickly and easily attached to the machine. TVH has lights in its range with nine different flashing patterns for extra visibility.

Wind meter

MEWPs for outdoor use are designed to withstand wind speeds up to a certain maximum. This maximum is always specified on the machine, as it’s important that the mobile elevating work platform isn’t operated at wind speeds above the maximum. Otherwise, this could lead to instability or, in extreme cases, could cause the machine to tip over.

That’s why wind speed should always be measured before entering the platform. This can be done with a wind meter, also known as a wind gauge or an anemometer. Modern wind meters come with a Bluetooth connection and a smartphone app, and can usually display more than just the wind speed and direction. Some types also measure the temperature, humidity and air pressure. TVH offers several types of wind meters, as well as magnetic tripods and self-levelling mounting brackets for secure mounting.

Ground protection mats and outrigger pads

Not only wind speed affects the stability of mobile elevating work platforms, but the surface on which the machine is standing or being driven also plays a crucial role. In case of soft or uneven terrain, ground protection mats can provide a safe and solid base for the MEWP to travel over. These mats are also useful to protect the delicate zones that normally aren’t accessible with heavy equipment, such as golf courses, festival grounds, etc.

Another way to keep mobile elevating work platforms stable is with outrigger pads. They distribute the ground pressure better, which prevents the machine from slipping and sinking into soft ground. But outrigger pads can also be handy indoors to protect floors, as some types have an integrated non-marking rubber base.

Protect the environment and equipment

Wheel covers

To prevent damage to particularly delicate floors, for instance in showrooms and exhibition halls, or in older buildings during renovation work, it’s best to cover the wheels of the mobile elevating work platform. Important to know, however, is that intensive use of wheel covers will reduce their lifespan.

Corner protection

Not only the floor can be delicate, but surrounding structures may also need extra protection. In this case, it’s a good idea to install corner protection on the platform rails. These guards are made of soft rubber and prevent damage to both the environment and the machine.

Protective covers

Bad weather can wreak havoc on the steering control unit of mobile elevating work platforms. But with a water-resistant protective cover made from PVC-coated fabric with polyester tissue, weather elements don’t stand a chance.

Security

Protecting the equipment also means securing the MEWP against theft. This can be achieved with a wheel clamp, equipped with a numerical safety lock with a four-digit code. TVH has both a small and a large model in its range. The former is suitable for a tyre width of 160 mm to 360 mm, the latter for 195 mm to 420 mm.

Maximum efficiency

Hydraulic generator

When working at height, it can be difficult to have a power supply for small and heavy power tools. A hanging cable reel is far from safe and an external power supply is rather expensive. The solution is a hydraulic generator, which can be connected to the hydraulic circuit of MEWPs to provide all the power required. Hydraulic generators are available in a range of electric potentials, including 110 V and 230 V.

Aerial Tool Bin

If there’s a chance that the MEWP operator will need a lot of tools and parts when they’re in the air, an Aerial Tool Bin could come in handy. This accessory can be attached to the corners of the platform’s railing and is strong enough to hold all the items the operator will need.

Ready to order?

- Browse even more parts in our ‘Replacement parts for mobile elevating work platforms’ catalogue.

- Buy these accessories and other parts for MEWPs in our online shop.

- Please feel free to contact us if you have any other questions.

About the authors

This blog post is brought to you by your construction equipment marketing team.